Heavy Duty Pulley Wheels and Belts for Industrial Use

Our company specializes in supplying high-quality products for industrial applications. Our range of products includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and much more. We pride ourselves on providing our customers with top-notch products, reasonable prices, and excellent customer service. Our customers are always welcome to submit their own drawings and samples for custom orders.

Product Description

Our heavy-duty pulley wheels, belts, and sheaves are designed for use in demanding industrial environments. We offer a wide variety of materials, including plastic, small aluminum, compound, and cast iron, to suit your specific needs. Our poly v sheaves and multi-ribbed rope cables are ideal for high-speed applications and provide reliable power transmission. Our tension pulleys are designed to keep belts tight and prevent slippage, ensuring efficient operation of your equipment.

We also offer a range of winches, including cable winches and hand winches, for lifting and pulling heavy loads. Our winches are made with the highest-quality materials and are built to withstand the toughest conditions. We also offer a range of gearbox options, including electric motor pulleys and flat belt gearboxes, to provide you with the power and speed you need for your application.

Benefits of Our Products

Our heavy-duty pulley wheels, belts, and sheaves are designed to provide reliable and efficient operation in even the most demanding industrial environments. Our products are made from high-quality materials and are built to last, ensuring long-term performance and durability. We also offer competitive pricing and excellent customer service, making us the ideal choice for all of your industrial needs.

Customization Options

At our company, we understand that each customer has unique requirements and specifications. That's why we offer customized solutions to meet your specific needs. Whether you need a specific size or material, we can work with you to create the perfect product for your application.

Expert Advice and Support

Our team of experts is available to provide you with advice and support throughout the entire process. From selecting the right product to customizing it to your specifications, we are here to help you every step of the way.

Quality Assurance

We take quality seriously and ensure that all of our products meet the highest standards of quality and performance. We conduct rigorous testing and inspection to ensure that our products meet or exceed your expectations.

FAQs

1. What materials are your pulley wheels made of?

We offer a wide variety of materials for our pulley wheels, including plastic, small aluminum, compound, and cast iron. We can also customize the material to meet your specific needs.

2. What are the benefits of using your tension pulleys?

Our tension pulleys are designed to keep belts tight and prevent slippage, ensuring efficient operation of your equipment. They are built to last and are made from high-quality materials, providing reliable and long-lasting performance.

3. Do you offer customized solutions?

Yes, we offer customized solutions to meet your specific needs. Whether you need a specific size or material, we can work with you to create the perfect product for your application.

4. What types of winches do you offer?

We offer a range of winches, including cable winches and hand winches, for lifting and pulling heavy loads. Our winches are made with the highest-quality materials and are built to withstand the toughest conditions.

5. What gearbox options do you offer?

We offer a range of gearbox options, including electric motor pulleys and flat belt gearboxes, to provide you with the power and speed you need for your application. We can also customize the gearbox to meet your specific needs.

This is a placeholder for the h1 heading

Disclaimer: All content in this article is sourced from the Internet and is provided for reference purposes only. Our products are replacement parts, not original spare parts. We do not own the trademarks mentioned in the content. Our replacement parts are perfectly compatible with the original spare parts. For original spare parts, please contact the respective manufacturer or supplier.

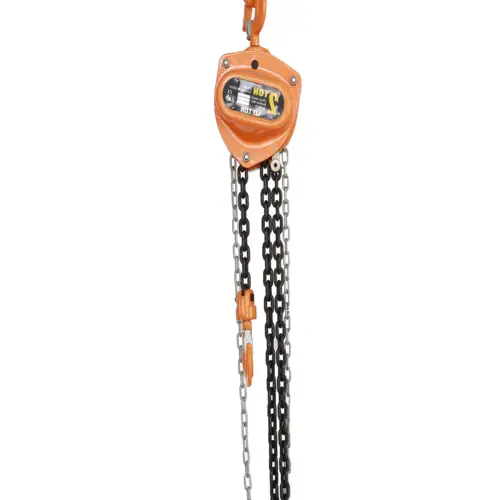

Performance Characteristics of Winch Pulley

Winch pulleys are known for their exceptional performance and numerous advantages:

- High Load Capacity: Winch pulleys are designed to handle heavy loads efficiently.

- Durable and Sturdy: These pulleys are made from high-quality materials, ensuring durability and long-lasting performance.

- Smooth Operation: Winch pulleys are engineered to provide smooth and reliable operation.

- Easy Installation: These pulleys are designed for easy and hassle-free installation.

- Versatility: Winch pulleys can be used in various applications and industries.

Types and Characteristics of Winch Pulley

Winch pulleys come in different types, each with its own unique characteristics:

Single Sheave Pulley

A single sheave pulley has a single groove for the rope or cable to pass through. It is lightweight, compact, and ideal for light to medium-duty lifting tasks.

Double Sheave Pulley

A double sheave pulley has two grooves, allowing for increased lifting capacity and better load distribution. It is suitable for heavier lifting applications.

Snatch Block Pulley

A snatch block pulley is designed to change the direction of the pulling force. It provides mechanical advantage and is commonly used in winching and rigging operations.

Wire Rope Pulley

A wire rope pulley is specifically designed to work with wire ropes. It features grooves or channels that prevent the rope from slipping.

Advantages of Winch Pulley Materials

Winch pulleys can be made from various materials, each offering distinct advantages:

Steel Winch Pulley

Steel winch pulleys are known for their strength and durability. They can withstand heavy loads and harsh conditions, making them suitable for demanding applications.

Aluminum Winch Pulley

Aluminum winch pulleys are lightweight and corrosion-resistant. They are ideal for applications where weight reduction is necessary without compromising strength.

Nylon Winch Pulley

Nylon winch pulleys are lightweight, non-conductive, and resistant to corrosion. They are commonly used in electric winches and applications where noise reduction is desired.

Application of Winch Pulley

Winch pulleys find widespread use in various fields and industries, including Construction, Marine, Automotive, Mining, and Forestry. Their versatility and reliability make them indispensable in these sectors.

Future Development Trends and Opportunities

The future of winch pulley products looks promising, with several development trends and opportunities on the horizon. Industries are constantly evolving, and winch pulleys will continue to play a crucial role in addressing the needs of these changing landscapes.

Some potential industry development prospects include:

- Technological advancements in winch pulley design and materials

- Innovative applications and integration with automation

- Increased focus on safety and efficiency

- Growing demand for eco-friendly and sustainable winch pulley solutions

Choosing a Suitable Winch Pulley

When selecting a winch pulley, several factors should be considered:

- Load Capacity: Assess the maximum load requirements and ensure the pulley can handle the intended weight.

- Material: Choose a material based on the specific application requirements, considering factors like strength, weight, and corrosion resistance.

- Diameter and Size: Determine the appropriate pulley size based on the diameter and thickness of the rope or cable used.

- Type of Pulley: Consider the type of pulley (single sheave, double sheave, snatch block, wire rope) suitable for the intended task.

- Bore Size: Ensure the pulley's bore size matches the diameter of the axle or shaft it will be mounted on.

Summary

Winch pulleys are essential components in various industries, offering exceptional performance and reliability. Understanding their performance characteristics, types, materials, and applications is crucial for selecting the right winch pulley for specific tasks. As industries continue to evolve, winch pulleys will play a vital role in meeting emerging needs and driving future advancements.

Author: Dream